is standard for vickers hardness testing|vickers hardness test chart : chain store The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials to Vickers and Knoop). 362K Followers, 76 Following, 1,740 Posts. Check out the latest photos and videos from andreiagadelhapro on Instagram after you follow them.

{plog:ftitle_list}

30 de set. de 2023 · falando sobre a WINPIX.ONLINE, e fralda ou não sobre os 1000 reais, como não vi ninguém falando sobre ela, vim aqui falar dela, ao me desculpem por que não s.

vickers hardness testing procedure

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials to Vickers and Knoop).The recommended hardness ranges for Vickers tests, which depend on the .

• Meyers and Chawla (1999). "Section 3.8". Mechanical Behavior of Materials. Prentice Hall, Inc.• ASTM E92: Standard method for Vickers hardness of metallic materials (withdrawn and replaced by E384-10e2)• ASTM E384: Standard Test Method for Knoop and Vickers Hardness of Materials

2008 range rover sport hse hard key test form meaning

Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. Significance and Use. 4.1 Vickers and Knoop hardness tests have been found to be .INTERNATIONAL STANDARD. ISO 6507-4:2018(E) Metallic materials — Vickers hardness test — Tables of hardness values. 1 Scope. ISO 6507-1. d cument gives tables of Vickers .This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials, including hard metals and other cemented carbides (see Table 1), .Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our complete range of hardness testing machines. See our hardness testing conversion table. DEFINITION OF THE VICKERS HARDNESS TEST. The Vickers hardness .

The Brinell hardness testing standard is ASTM E10. For both Vickers and Brinell hardness testing, it is common to use reference tables to give the value of hardness for a given .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low .

EN ISO 6507-1 and ASTM E92 are two widely recognized standards for Vickers hardness testing, both of which use a similar test method and offer multiple test force options. .Vickers hardness testing is carried out to standards such as ASTM E384 or ISO 6507 which has four parts describing the test itself, calibration and hardness tables. 9.11.2 Brinell hardness test An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.

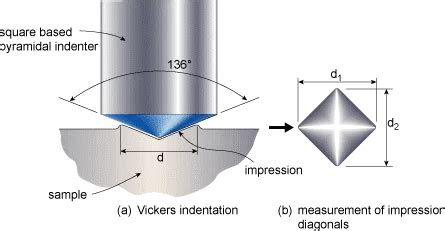

Indian Standard METHOD FOR VICKERS HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) Ics 77.040.10 0 61s 2002 BUREAU OF INDIAN STANDARDS MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG NEW DELHI 110002 October 2002 Price f% 600.00 L, Mechanical Testing of Metals Sectional Committee, MTD 3 Standards: EN ISO 6507 / ASTM E18 Rockwell Methods 1.2. Page 7 E74 Practice of Calibration of Force-Measuring Instruments 3.1.5 Vickers hardness test, n—an indentation test in which for Verifying the Force Indication of Testing Machines a Vickers square-based pyramidal diamond indenter having E140 Hardness Conversion Tables for Metals Relationship specified face angles is forced under specified . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Standard Hardness Conversion for metals acc. ASTM E 140 – 97 .

Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: . Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific .Vickers Hardness Testing Formulas, Calculator and Review . . The loads applied vary from 1 to 120 kg; the standard loads are 5, 10, 20, 30, 50, 100, and 120 kg. For most hardness testing, 50 kg is maximum. A Vickers hardness tester should be calibrated to meet ASTM standard E10 specifications, acceptable for use over a loading range.

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.This is a multi-part document divided into the following parts: Part 1 Metallic materials.Vickers hardness test. Test method; Part 2 Metallic materials.Vickers hardness test. Verification of testing machinesMetallic materials — Vickers hardness test — Part 1: Test method. Metallic materials — Vickers hardness test — Part 1: Test method. Skip to main content. Applications . Withdrawal of International Standard Edition : 4. Number of pages : 30. Technical Committee : ISO/TC 164/SC 3. ICS : 77.040.10 RSS updates; Life cycle. Previously .Vickers hardness test sangat ideal untuk pengujian semua logam dan karenanya merupakan metode dengan rentang aplikasi terluas.Hardness test method menurut Vickers dijelaskan dalam standar ISO 6507 (Bahan logam – Uji kekerasan Vickers – Bagian 1: Metode uji) dan ASTM E384 (Metode Uji Standar untuk Kekerasan Mikroindentasi Bahan terhadap Vickers .

In order to avoid misinterpretations of the perceived hardness, the standards prescribe a certain distance between multiple indentations. Examples of indent spacing in the Vickers hardness test for metallic materials . For steel, copper, and copper alloys: Spacing between indents must be at least three diagonal widths . Vickers and Knoop hardness test methods are defined in the following standards: ASTM E384 and ISO 6507. It is recommended that operators have a current copy. . The only difference between standard .Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. The comprehensive range of scales and blocks, associated with Rockwell, Brinell, Vickers and Knoop testing.

among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, and Knoop hardness of copper. 1.8 Conversion Table 8 presents data on the relationshipDepending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range.

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .The Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an indenter when it is pressed with a fixed load. You can also use it to measure the indentation hardness of non-metallic materials, provided they are sufficiently dense.

EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

As the name indicates, a Vickers hardness tester is specialized for hardness testing according to the Vickers method.Many Vickers hardness testers can also cover Brinell and Knoop test methods.. These instruments support standard compliant testing of different materials and component geometries across a wide range of industries.

The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). . Vickers. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers .ISO 6507-1:2005 specifies the Vickers hardness test method for the three different ranges of test force for metallic materials. The Vickers hardness test is specified in ISO 6507-1:2005 for lengths of indentation diagonals between 0,020 mm and 1,400 mm.STANDARD ISO 6507-4 Second edition 2018-02 . ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method 3 Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminological databases for use in standardization at the following addresses: 5.1 For advanced ceramics, Vickers indenters are used to create indentations whose surface-projected diagonals are measured with optical microscopes. The Vickers indenter creates a square impression from which two surface-projected diagonal lengths are measured. Vickers hardness is calculated from the ratio of the applied force to the area of contact of the .

2011 macbook air hard drive test won't boot

WEB27 de dez. de 2023 · Kate Kuray

#katekurayhub@cute_girl.photo

is standard for vickers hardness testing|vickers hardness test chart